Cycloaliphatic amine epoxy resin has emerged as a game-changing material in advanced industrial applications, offering superior chemical resistance, durability, and thermal stability. Jiangsu Tetra New Material Technology Co., Ltd., a leading manufacturer since 2004, specializes in high-performance cycloaliphatic epoxy resins at their production bases in Taixing, Jiangsu, catering to global demand for specialized coatings and composite applications.

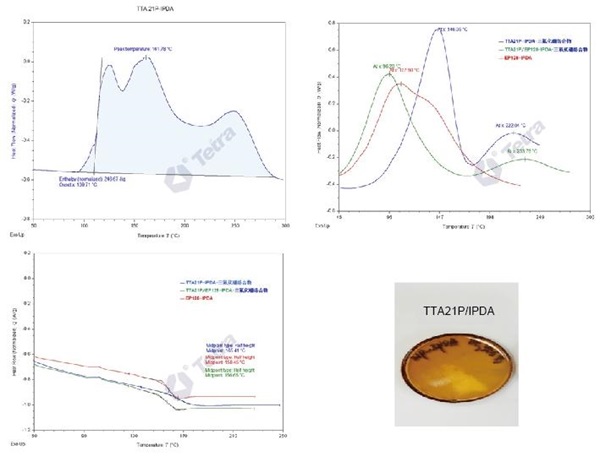

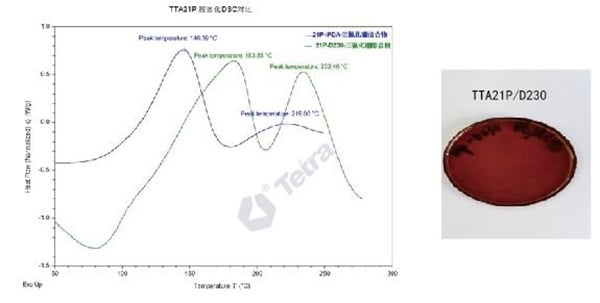

Unlike conventional resins, cycloaliphatic amine epoxy provides enhanced mechanical strength, exceptional UV resistance, and superb adhesion properties. At Tetra, our advanced formulations ensure high-performance results in demanding environments, making it ideal for coatings, adhesives, and corrosion-resistant linings. The exceptional thermal stability and reduced viscosity of our resins also allow for better processing flexibility while maintaining structural integrity.

Cycloaliphatic amine epoxy resins derive their robustness from a saturated ring structure, which significantly improves resistance to yellowing, weathering, and chemical degradation. Tetra’s expertise in fine chemical engineering allows us to optimize these properties for industries such as aerospace, automotive, and marine coatings. Our resins excel in applications requiring long-term durability, including protective industrial coatings, electrical encapsulation, and structural composites.

A key factor in selecting an epoxy system is understanding how it compares to alternatives. The table below highlights the differences between cycloaliphatic amine epoxy and traditional amine hardeners:

Property | Cycloaliphatic Amine Epoxy | Traditional Amine Hardeners |

UV & Yellowing Resistance | Excellent | Poor |

Chemical Resistance | Superior | Moderate |

Thermal Stability | High (up to 180°C+) | Limited (below 120°C) |

Curing Flexibility | Wide operating window | Narrow curing conditions |

Tetra's cycloaliphatic variants provide a clear advantage in high-demand settings where durability and stability are critical.

Industries requiring protection against harsh solvents, acids, and alkalis are increasingly turning to cycloaliphatic amine epoxy for long-lasting performance. As a trusted aliphatic epoxy supplier, Tetra’s formulations enhance corrosion resistance in oil & gas pipelines, chemical storage tanks, and marine structures, minimizing maintenance costs and extending service life. The material’s ability to maintain adhesion even in extreme pH conditions makes it indispensable for modern protective coatings.

Selecting the optimal epoxy resin depends on factors like environmental exposure, curing conditions, and mechanical load requirements. Tetra New Material Technology offers tailored specialty epoxy resins solutions, whether for high-temperature industrial coatings or flexible adhesives. Our technical team assists in testing and customization to match specific project needs, ensuring optimal performance from formulation to application.

With nearly two decades of expertise, Tetra is a trusted global supplier of cycloaliphatic amine epoxy resins. Our commitment to R&D, quality control, and customer-driven solutions ensures that industries receive high-performance materials built for longevity.