3D printing is a rapid prototyping technology. By UV light, liquid photosensitive polymers are transformed into solid molding parts, with strong controllability, simple operation, and high precision. SLA, as a common form of 3D printing, typically produces larger-size products, which must overcome challenges such as oxygen inhibition and high shrinkage rates. A UV cationic system–based Cycloaliphatic Epoxy Resin is widely used in epoxy resin 3d printing formulations to solve these issues. The integration of lipid ring epoxy groups improves mechanical properties and significantly enhances curing speed, making it suitable for high-performance epoxy printing applications.

UV Cationic system-based Cycloaliphatic Epoxy Resin has the advantages of low shrinkage, no oxygen resistance, low viscosity, and good heat resistance. The development of special epoxy resin for 3D printing has revolutionized the industry by providing enhanced strength, durability, and precision in printed components.

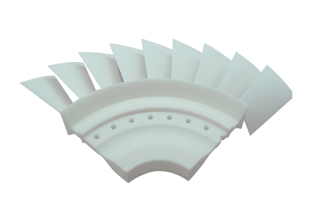

Specialty epoxy resins are known for their high strength and durability, making 3d printing epoxy resin ideal for 3D printing applications that require strong, long-lasting parts. Epoxy resins have high thermal stability, which means epoxy resin 3d printing can withstand high temperatures without deforming or breaking down. This makes this Tetra material suitable for 3D printing parts that will be exposed to high temperatures during use.