Insulation epoxy resins function as dielectric barriers that prevent electrical current leakage while offering mechanical protection and thermal management. When applied as coatings or encapsulation materials, they form a non-conductive, high-strength layer around conductors and components. Tetra's cycloaliphatic epoxy-based insulators are particularly effective due to their low ionic impurity levels, ensuring high volume resistivity (typically >10¹⁶ Ω·cm) and excellent tracking resistance.

The cross-linked molecular structure of cured epoxy provides superior adhesion to metals, ceramics, and composite substrates. During operation, it maintains stable insulation properties even when exposed to moisture, chemicals, or thermal cycling—a critical advantage over alternative materials.

Selecting the optimal insulation material requires understanding how modern epoxy resins outperform conventional solutions. The comparison below highlights why Tetra's insulation epoxies are increasingly replacing traditional options in power systems:

Property | Insulation Epoxy (Tetra) | Traditional Materials (Ceramic/Phenolic) |

Dielectric Strength | >20 kV/mm | 12-15 kV/mm (ceramic) / 10-12 kV/mm (phenolic) |

Thermal Conductivity | 0.2-0.3 W/m·K (better heat dissipation) | 1-2 W/m·K (ceramic, may cause localized hotspots) |

Mechanical Strength | High flexural/tensile strength (≥80 MPa) | Brittle (ceramic) or prone to delamination (phenolic) |

Weight | Lightweight (1.1-1.3 g/cm³) | Heavy (ceramic: 2.5+ g/cm³) |

UV/Chemical Resistance | Excellent (no degradation in outdoor/chemical exposure) | Poor (phenolic absorbs moisture; ceramic cracks under thermal shock) |

For transformers, bushings, and switchgear, our insulation epoxy resins provide lighter, more durable, and easier-to-install alternatives without compromising electrical safety.

In transformer insulation systems, ceramic coatings have historically been used for their high-temperature tolerance. However, advanced insulation epoxy resins like Tetra's cycloaliphatic formulations now dominate due to three decisive advantages:

Seamless Protection: Unlike ceramic tiles with joints, epoxy forms a continuous, void-free layer, eliminating partial discharge risks that accelerate insulation failure.

Vibration Resistance: Transformers generate mechanical vibrations where brittle ceramics may crack. Epoxy's elastic modulus absorbs vibrations without damage.

Repairability: Damaged ceramics require complete replacement, while Tetra's epoxies allow localized repairs—reducing downtime and maintenance costs.

Additionally, our resins' CTI (Comparative Tracking Index) >600V ensures reliability even in polluted or humid environments, a frequent challenge for ceramic-coated transformers.

Insulation epoxy resins must maintain stable dielectric properties across a broad temperature range. Tetra's cycloaliphatic epoxies are engineered to operate from -50°C to +180°C with minimal tan δ (loss tangent) increase, critical for:

- Cold climates: Avoids microcracking thanks to low glass transition temperature (Tg) modifiers.

- Overload conditions: Retains >80% of dielectric strength even at 150°C+, unlike generic epoxies that soften above 100°C.

In high-power transformers, our resins' thermal conductivity (~0.25 W/m·K) helps dissipate hotspots, while their coefficient of thermal expansion (CTE) closely matches copper windings, reducing interfacial stresses during load cycles.

Choosing an insulation epoxy for high-voltage systems (e.g., GIS, cables, or generators) depends on four critical parameters:

- Dielectric Strength: Tetra's formulations achieve >20 kV/mm (ASTM D149), suitable for EHV (Extra High Voltage) equipment.

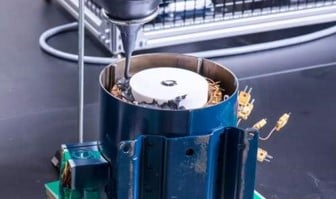

- Partial Discharge Resistance: Our ultra-low viscosity epoxies penetrate winding gaps to eliminate air voids ≥50 μm—a key failure point.

- Curing Profile: For thick-section castings, Tetra offers slow-curing resins that prevent exothermic cracking.

- Environmental Compliance: Halogen-free and RoHS-compliant options are available for sustainable energy projects.

We provide customized solutions for DC insulation (>500 kV) and AC systems (50-60 Hz), with optional silica fillers to enhance arc resistance.

With 20+ years of expertise, Tetra New Material delivers high-reliability insulation epoxy resins for global energy infrastructure. Our Taixing R&D center continually innovates in:

- Cycloaliphatic epoxy formulations for outdoor insulators (UV/rain erosion resistant)

- Low-viscosity encapsulation resins for compact power electronics

- Fire-retardant grades (UL94 V-0 compliant) for substation applications