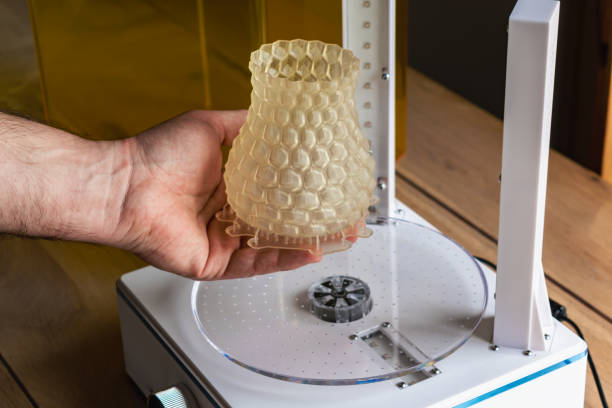

Epoxy resin has become a cornerstone in high-precision 3D printing due to its unique mechanical and chemical properties. Unlike conventional thermoplastics used in FDM (Fused Deposition Modeling), Tetra's cycloaliphatic epoxy resins provide ultra-low shrinkage (<0.3%), ensuring micron-level accuracy in printed parts. This is particularly valuable for industries requiring tight tolerances, such as microfluidics, aerospace components, and medical implants.

Another key advantage is exceptional interlayer adhesion, which eliminates delamination risks in layer-by-layer printing processes. Additionally, epoxy-based photopolymers cure rapidly under UV light (in SLA/DLP methods), achieving full polymerization with minimal post-processing. Combined with high heat resistance (up to 180°C after thermal treatment), these characteristics make Tetra's epoxy resins a top choice for functional prototyping and production-grade 3D printing.

Selecting the right material for additive manufacturing requires a detailed understanding of performance trade-offs. Below is a comparison between Tetra's epoxy resins and mainstream 3D printing materials:

Property | Epoxy Resin 3D Printing (Tetra) | Traditional FDM (PLA/ABS) | SLS (Nylon PA12) |

Tensile Strength | 50-80 MPa | 30-50 MPa (PLA) / 40-45 MPa (ABS) | 48-52 MPa |

Dimensional Accuracy | ±0.05-0.1 mm | ±0.2-0.5 mm | ±0.1-0.3 mm |

Temperature Resistance | Up to 180°C (post-cured) | 60-100°C (softening point) | 120-140°C |

Surface Finish | Smooth, near-injection molding | Visible layer lines | Slightly grainy |

Chemical Resistance | Excellent (solvents, oils) | Poor (PLA degrades in moisture) | Moderate |

This data highlights why industries transitioning to high-stakes applications—such as automotive tooling or medical devices—increasingly favor epoxy resin-based 3D printing.

Epoxy resin's versatility makes it indispensable across multiple industrial 3D printing sectors:

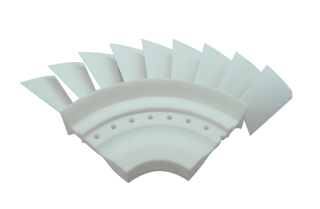

- Aerospace Tooling: Tetra's resins are used for jigs, fixtures, and wind-tunnel prototypes due to their high strength-to-weight ratio and heat deflection stability.

- Automotive Molds: Injection molding inserts printed with epoxy resins withstand high-pressure cycles without deformation, reducing lead times versus metal tooling.

- Electronics Encapsulation: Low-viscosity epoxy formulations enable precise printing of microelectronic housings, offering superior insulation and moisture protection.

These applications leverage epoxy's ability to produce end-use parts with tight tolerances and complex geometries, making it a cost-effective alternative to CNC machining or casting.

To maximize the performance of epoxy resin 3d printing, careful post-curing optimization is essential. Our technical studies indicate that:

- UV Wavelength & Intensity: 385-405 nm UV lamps achieve deeper curing versus standard 355 nm lasers, reducing internal stresses.

- Temperature-Controlled Curing: Heating prints to 60-80°C for 1-2 hours post-UV exposure enhances crosslinking density, boosting HDT (Heat Deflection Temperature) by 20-30°C.

- Oxygen Inhibition Mitigation: Printing in nitrogen-purged chambers minimizes surface tackiness, critical for medical or optical-grade components.

Tetra's epoxy resins are engineered for broad compatibility with commercial 3D printers, ensuring repeatable, high-quality outputs across different curing setups.

The medical industry is rapidly adopting epoxy resin 3D printing for three critical reasons:

Biocompatibility Potential: Certain cycloaliphatic epoxy grades meet ISO 10993 standards for short-term skin contact, enabling surgical guides and dental models.

Sterilization Resistance: Unlike ABS or PLA, fully cured epoxy parts endure autoclaving (134°C steam) without warping—a must for reusable instruments.

Micro-Feature Replication: Dental aligners or hearing aid shells printed with Tetra's resins achieve <20 μm feature resolution, surpassing conventional methods.

Leading orthopedic implant developers also utilize epoxy-based 3D printing for patient-specific porous structures that promote bone ingrowth, demonstrating the technology's transformative potential.

For nearly two decades, Tetra New Material has pioneered specialty epoxy resins that redefine industrial 3D printing capabilities. Our expertise includes:

- Customized formulations for high-speed DLP printing (reducing build time by 30%)

- Low-odor, non-yellowing resins for consumer product prototyping

- Thermally conductive grades (up to 1.2 W/m·K) for heat exchanger applications

Accelerate your additive manufacturing projects with Tetra's high-performance resins.