In the world of high-performance epoxy resins, cycloaliphatic amine epoxy has emerged as a superior choice for industries requiring exceptional durability and chemical resistance. As a leading manufacturer of specialty epoxy resins, Jiangsu Tetra New Material Technology Co., Ltd. has been at the forefront of developing innovative cycloaliphatic amine epoxy solutions since 2004.

Cycloaliphatic amine epoxy resins stand out due to their unique molecular structure, which provides excellent mechanical strength, thermal stability, and resistance to environmental factors. Unlike conventional epoxy systems, these resins maintain their properties even under extreme conditions, making them ideal for applications where long-term performance is critical. Tetra's formulation expertise ensures these resins deliver consistent quality across various industrial applications.

The exceptional characteristics of cycloaliphatic amine epoxy stem from its saturated carbon ring structure, which provides inherent resistance to yellowing and degradation caused by UV exposure. This scientific advantage translates into practical benefits for industries such as aerospace, automotive, and protective coatings, where materials must withstand harsh environmental conditions without compromising performance. The molecular stability also contributes to better dielectric properties, making these resins suitable for electrical applications.

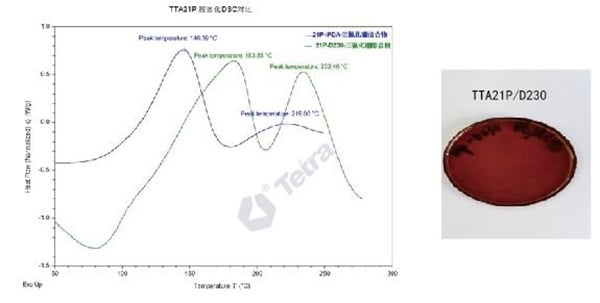

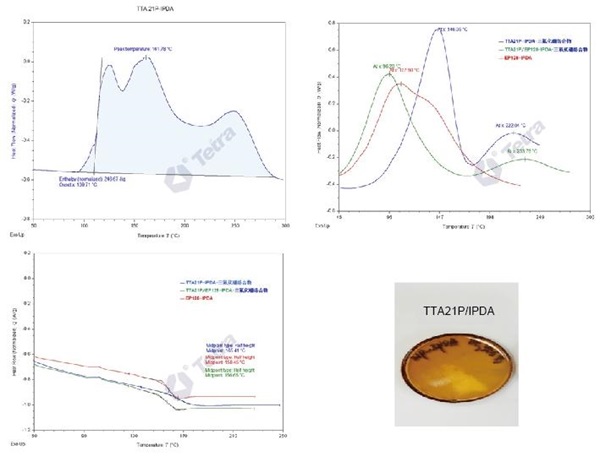

When evaluating epoxy resin options, it's essential to understand how cycloaliphatic amine epoxy compares to traditional alternatives. While conventional aromatic epoxy resins may offer initial cost advantages, they often fall short in terms of UV resistance and long-term stability. Cycloaliphatic formulations, on the other hand, demonstrate superior performance in maintaining mechanical properties under thermal stress and chemical exposure. This advantage becomes particularly significant in outdoor applications or environments with fluctuating temperatures. The investment in cycloaliphatic amine epoxy often proves cost-effective when considering total lifecycle performance.

The chemical resistance properties of cycloaliphatic amine epoxy have transformed protective coating solutions across multiple industries. These resins form dense, crosslinked networks that effectively block corrosive agents, making them indispensable for chemical processing equipment, marine structures, and oil and gas infrastructure. Tetra's specialized formulations provide even greater resistance to acids, alkalis, and solvents, extending the service life of coated surfaces while reducing maintenance requirements.

Choosing the appropriate cycloaliphatic amine epoxy formulation requires careful consideration of application requirements and environmental conditions. Factors such as curing temperature, pot life, and final mechanical properties should guide the selection process. Tetra's technical team assists customers in navigating these decisions, offering tailored solutions that optimize performance for specific applications. From high-temperature resistant coatings to durable industrial adhesives, the versatility of cycloaliphatic amine epoxy makes it adaptable to diverse industrial challenges.

As industries continue to demand more robust and durable material solutions, cycloaliphatic amine epoxy resins remain at the cutting edge of material science. Tetra's commitment to innovation ensures that these advanced epoxy systems continue to evolve, meeting the ever-changing needs of modern industrial applications while maintaining the highest standards of performance and reliability.