Insulation epoxy is a class of epoxy-based electrical insulation materials formulated by combining epoxy resin with curing agents and functional fillers. It exhibits excellent dielectric properties, chemical resistance, and adhesion, making it suitable for:

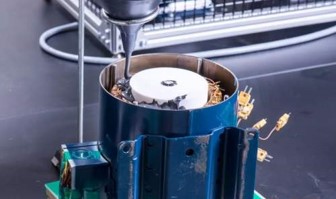

Potting electronic components

Coating motor windings

Encapsulating printed circuit boards

Its main function is to prevent electric shock, leakage, and interference from environmental factors. Widely used in low-voltage devices, industrial control systems, and high-voltage equipment, insulation epoxy plays a critical role in maintaining electrical safety and reliability.

However, with the growing demands of modern high-density and high-power electronics, thermal management has become increasingly crucial. Traditional insulation epoxy is no longer sufficient to handle both heat conduction and electrical isolation simultaneously.

| Property | Description | Functional Benefit |

|---|---|---|

| Ultra-low thermal conductivity | Incorporates ceramic micropowders or hollow microspheres with low thermal transfer rates | Effectively blocks heat flow, protecting temperature-sensitive components |

| Stable electrical insulation | Maintains dielectric strength even under elevated temperatures | Ensures reliable operation in high-heat environments |

| Process adaptability | Supports molding, potting, or spray coating | Compatible with various industrial manufacturing processes |

Thermal insulation epoxy is designed to deliver superior thermal resistance while maintaining excellent electrical insulation. It is especially useful in compact and heat-sensitive systems where dual-function protection is needed.

High-Power Electronic Devices

Used in electric vehicles, 5G base stations, and high-frequency power supplies where localized heat is intense. Thermal insulation epoxy forms a heat barrier to protect critical circuits and enhance operational stability and lifespan.

Precision Sensors and Measuring Instruments

In temperature-sensitive components like photodetectors and thermocouples, it minimizes thermal interference and signal deviation, thus improving measurement accuracy.

Aerospace and Defense Equipment

Applied in radar systems, missile electronics, and satellite modules to prevent performance drift caused by heat radiation or conduction in extreme environments.

Semiconductor Packaging

Helps reduce thermal shock and mismatch in thermal expansion, improving the reliability of chip packaging structures exposed to fluctuating temperatures.

As high-performance electronics and smart devices continue to evolve, conventional insulation epoxy remains foundational. However, for more advanced thermal control needs, thermal insulation epoxy is becoming indispensable. With its ability to block heat while maintaining dielectric strength, it offers crucial protection in temperature-sensitive designs.

In an era of miniaturization, high-frequency operation, and system integration, thermal insulation epoxy will increasingly serve as the "invisible barrier" enabling safe, stable, and reliable performance across a broad range of industrial sectors.