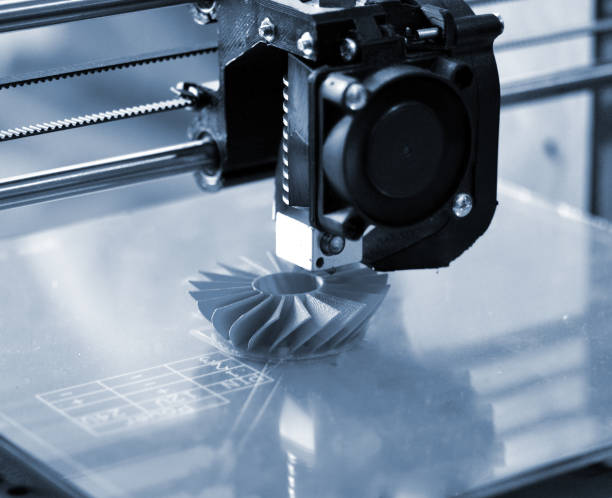

Thanks to their unique material properties and precision molding capabilities, epoxy resin 3D printers are widely used across multiple high-end manufacturing sectors.

Mold Making & Rapid Prototyping

In product development, fast prototyping is essential. With epoxy resin 3D printing, engineers can quickly produce high-accuracy models or even directly print low-pressure injection molds—greatly reducing the time and cost from design to testing.

Electronics & Micro-Mechanical Components

Epoxy resins offer excellent electrical insulation and dimensional stability, making them ideal for producing electronic housings, precision connectors, and miniaturized sensor components.

Medical Customization & Dental Devices

Epoxy resin 3D printers perform remarkably well in healthcare, especially dentistry, where they are used for crowns, dental models, and surgical guides. Their high resolution and biocompatibility meet the rigorous safety and quality standards of the medical field.

Artistic Design & Jewelry Making

In the creative and jewelry industries, epoxy resin 3D printers are favored for their ability to render intricate textures and polished surfaces, making them perfect for printing sculptural prototypes and custom-designed jewelry pieces.

The following table outlines the key benefits of epoxy resin 3D printing across functional, mechanical, and industrial dimensions:

| Feature | Description | Application Value |

|---|---|---|

| High Precision & Surface Finish | Capable of producing ultra-smooth, detailed parts | Ideal for dental models, fine jewelry, and micro-mechanics |

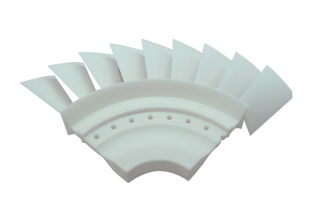

| Strong Mechanical Integrity | Excellent hardness, rigidity, and thermal stability in cured parts | Suitable for aerospace prototypes and end-use industrial components |

| Electrical Insulation | Epoxy materials naturally provide high dielectric strength | Used in electronics casings and insulating structures |

| Biocompatibility (optional) | Medical-grade epoxy formulations are non-toxic and skin-safe | Enables patient-specific medical and dental device printing |

| Moldability & Post-Processing | Easy to sand, polish, or machine after printing | Enhances aesthetics and precision in both artistic and industrial use |

With continued innovation in materials science, epoxy resin formulations are evolving to meet more specialized performance needs. Developments such as high-temperature resistance, impact tolerance, and ultra-clear optical grades are expanding the possibilities for epoxy resin 3D printers.

These advancements position epoxy-based printing as a promising replacement for traditional manufacturing in cutting-edge sectors such as:

Aerospace: for lightweight structural parts

Automotive: for thermal-resistant prototyping components

Advanced Electronics: for encapsulated circuits or packaging systems

As performance improves, epoxy resin 3D printing is set to unlock more complex, functional, and sustainable manufacturing applications.

By integrating superior material properties with high-resolution additive manufacturing, epoxy resin 3D printing is reshaping how industries approach design and fabrication. From personalized healthcare to scalable industrial parts, this technology is pushing beyond the limits of traditional processes.

As material innovation and printer intelligence continue to evolve, epoxy resin 3D printers will play a pivotal role in the transformation toward customized, precise, and intelligent manufacturing systems across diverse fields.