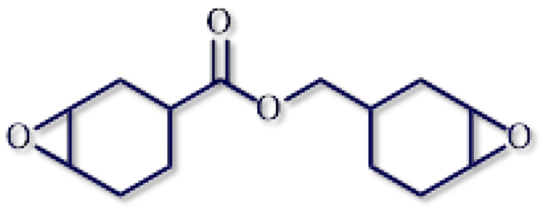

Alicyclic epoxy resin is a kind of low molecular compound, which contains alicyclic epoxy group. It is not a polymer instead, but can produce a polymer with 3D structure and very excellent performance through reacting with curing agent. It boasts special performance thanks to its special structure (epoxy group is directly connected to the saturated alicyclic structure instead of being connected to the benzene ring through ether bond as bisphenol A epoxy resin).

TTA21P

1.1 Small molecular weight, low viscosity and superior transparency.

1.2 High epoxy value, high crosslink density of cured product, high glass transition temperature and excellent heat resistance.

1.3 No benzene ring structure and hydroxyl group in molecule, excellent ultraviolet resistance and weather resistance.

1.4 Low chlorine content and dielectric constant and outstanding electrical insulation properties.

2.1 Low volatility, low toxicity and little irritation.

2.2 Large use level with and easy to mix with epoxy resin. Low viscosity after mixing; modification can be realized by adding a large number of fillers, which is beneficial to reducing cost.

2.3 Long service life, small heat release and easy operation.

2.4 High curing temperature and long curing cycle.

3.1 Commonly anhydride curing agents include tetrahydrophthalic anhydride, hexahydrophthalic anhydride, methyltetrahydrophthalic anhydride, methylhexahydrophthalic anhydride, methylnadic anhydride, etc.

3.2 Methyl hexahydrophthalic anhydride, a transparent liquid at room temperature with low viscosity, light color, easy operation, excellent curing performance, etc., is generally used as a curing agent for thermal curing of alicyclic epoxy resin.

Cured Products of Cycloaliphatic Epoxy Resin TTA21P After Curing via Methyl Hexahydrophthalic Anhydride

4.1 Excellent heat resistance: High heat distortion temperature and high glass transition temperature Tg (up to 200-210 ℃).

4.2 Excellent insulation performance: Especially under a high temperature environment, such as low dielectric constant and loss, high volume resistivity and excellent tracking resistance.

4.3 Good weather and yellowing resistance.

See the table below for the cycloaliphatic epoxy resins measured data:

_03.png)

In summary, alicyclic epoxy resin and the anhydride can be used together in such fields as LED packaging, electrical casting, insulation impregnation, insulation potting and composite materials.