Composite epoxy resin refers to an enhanced epoxy resin system that incorporates functional fillers, reinforcements, nanoparticles, or other resin components to improve mechanical strength, thermal stability, electrical insulation, or other target properties. Unlike standard epoxy resins, these composite systems can be engineered for customized performance through molecular design and compositional tuning.

For example:

Adding carbon nanotubes or graphene dramatically boosts thermal conductivity and tensile strength;

Incorporating ceramic powders or boron nitride improves dielectric strength and heat resistance.

Such resins are widely used in electrical insulation systems, thermal interface encapsulants, and structural adhesives across industrial and high-tech domains.

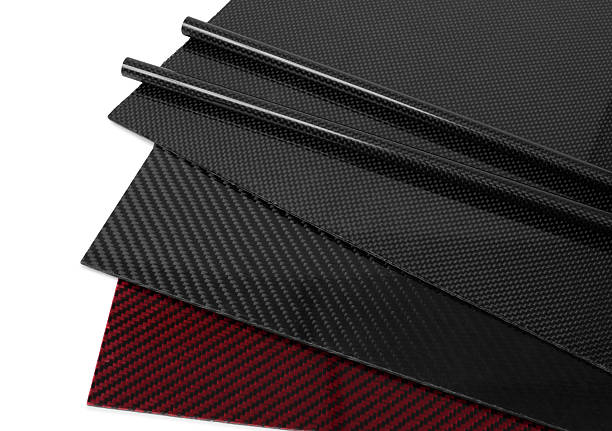

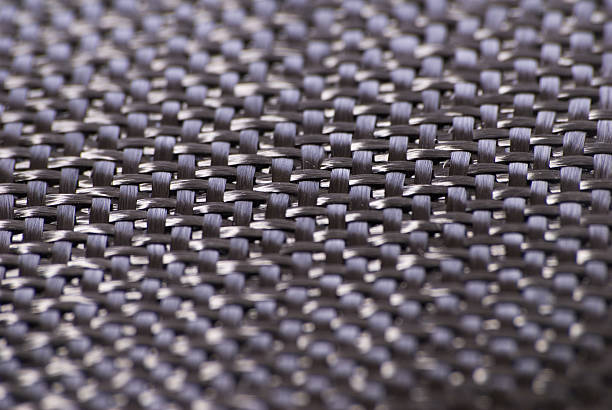

When a composite epoxy resin is combined with reinforcing fibers (such as glass fiber, carbon fiber, or aramid fiber), the result is a composite epoxy material—a structural composite with outstanding performance.

These materials offer:

Low weight with high mechanical strength

Fatigue resistance

Corrosion resistance

Widely employed in aerospace, rail transit, wind turbine blades, automotive lightweighting, and sporting equipment

The superior performance comes from a synergistic structure:

The resin matrix provides bonding and environmental protection;

The fiber reinforcement offers rigidity and mechanical strength.

Thus, composite epoxy materials serve as an "ideal framework" in structural component design.

| Aspect | Composite Epoxy Resin | Composite Epoxy Material |

|---|---|---|

| Definition | Functionalized resin matrix with additives and modifiers | Composite system made of epoxy resin matrix + fiber reinforcement |

| Primary Role | Acts as a binder, insulator, or thermal interface | Serves as structural and load-bearing component |

| Key Components | Epoxy resin + fillers/nanoparticles/other resins | Composite epoxy resin + fibers (glass, carbon, aramid, etc.) |

| Typical Applications | Electrical insulation, heat dissipation, adhesives | Aerospace, automotive parts, wind turbine blades, lightweight components |

| Processing Considerations | Formulated for castability, curing kinetics, or flow control | Requires molding, lamination, and structural design integration |

As industries move toward lightweight, high-performance, and environmentally friendly solutions, both composite epoxy resins and composite epoxy materials are becoming essential for advanced engineering.

Emerging trends include:

Green Formulations: Development of low-VOC, recyclable, and bio-based epoxy systems;

Smart Composites: Integration of sensing or self-healing functionalities into epoxy matrices;

High-Frequency Applications: Tailored dielectric properties for 5G, radar, and EV electronics;

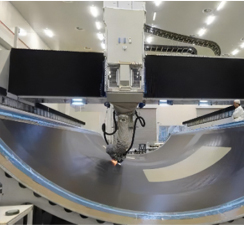

Precision Manufacturing: Use of additive manufacturing and automated fiber placement for complex geometries.

Through continuous material innovation and process optimization, composite epoxy systems will remain central to the design and manufacture of next-generation structural and functional materials.