Since the commercialization of cycloaliphatic epoxy resins in the 1950s and 1960s, the number of types of cycloaliphatic epoxy resin monomers available for commercialization has not exceeded 15. In 2004, Jiangsu Tetra cycloaliphatic epoxy resin manufacturer entered this field and has since grown into a leading global supplier of cycloaliphatic epoxy resins.

Through its Jiangsu Special Epoxy Resin Engineering Technology Center platform, Tetra continues to innovate and has about 50 new products at various stages of the technology chain.

TTA800 cycloaliphatic epoxy resin is a new type of structure that differs from TTA21 (3 4 epoxycyclohexylmethyl 3 4 epoxycyclohexane carboxylate) in that the two cycloaliphatic epoxy groups are connected by a non-ester bond. Based on the traditional characteristics of cycloaliphatic epoxy, it exhibits higher heat resistance, better resistance to boiling water, and higher photopolymerization activity, and has excellent adhesion to various common substrates with a rating of 0.

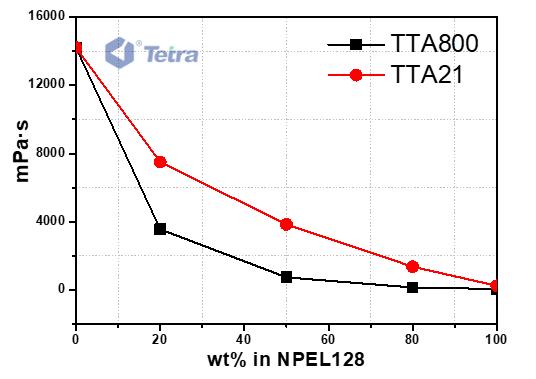

TTA800 has an extremely low viscosity and strong dilution ability, making it suitable for high filling systems.

Test conditions: DHR, 25℃

From the experimental data, it can be seen that TTA800 has an extremely low viscosity and strong dilution ability. Significant dilution effect can be achieved when the addition amount in the formulation exceeds 20%.

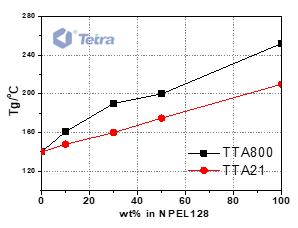

Properties: High Tg (~250℃), high modulus.

As can be seen from the figure, TTA800 has a high Tg after curing, and introducing other resin systems can significantly increase the system's Tg, thereby enhancing heat resistance.

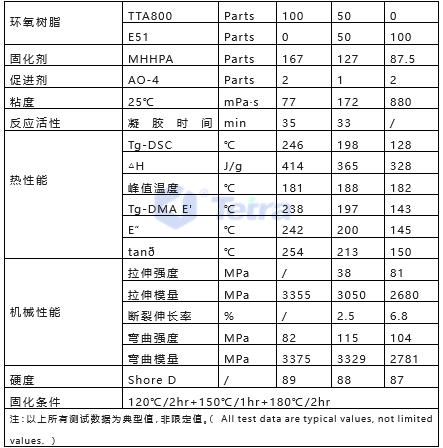

1、 Basic performance data of TTA800/E51 mixed anhydride thermosetting.

By adding TTA800, the heat resistance of the E51 system can be significantly improved. In addition, TTA800 cycloaliphatic epoxy resin has an extremely low viscosity, which can greatly reduce the mixed viscosity of the system when introduced into the formulation, bringing convenience in operation. Therefore, in the formulation design, suitable mixed addition ratios can be considered based on specific performance requirements according to the above basic data to achieve excellent comprehensive performance.

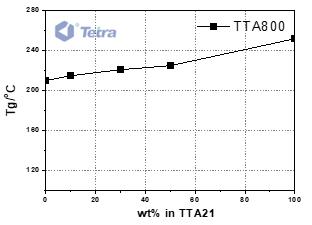

2、Performance of TTA800/TTA21 mixed anhydride thermosetting.

TTA21 is a general heat-resistant cycloaliphatic epoxy resin with a high Tg of over 200℃. However, when higher heat resistance is required, adding TTA800 cycloaliphatic epoxy resin can significantly improve the Tg and achieve higher heat resistance while maintaining low viscosity and good transparency.

TTA800 has excellent transparency and high heat resistance when cured with methylhexahydrophthalic anhydride (MHHPA), with a DSC-Tg of 246℃. When cured with methyl nadic anhydride (MNA), it can achieve even higher heat resistance, with a Tg of 275℃.

The above results show that TTA800 and MHHPA can produce cured products with excellent transparency and high heat resistance under the action of different curing agents, with a DSC-Tg of up to 246°C. Curing with MNA can achieve even higher heat resistance, with a Tg of up to 275°C. It can be observed that TTA800 and MHHPA can both produce cured products with high hardness, high Tg, and excellent transparency under the action of different curing agents. However, it can also be seen that DBU-Oct can achieve a higher Tg and has a lower gel time. 3100S reacts quickly with a low peak temperature, but its heat resistance is slightly lower compared to other types of curing agents. The type of curing agent used can have a certain degree of influence on the properties of the cured product. Compared with AO-4 and 3100S, using DBU octanoate and 2-ethyl-4-methylimidazole as curing agents can result in a higher Tg under the same other conditions. From the peak heat release of DSC, 3100S has a lower heat release and a faster curing rate, but the Tg after curing is slightly lower. Therefore, it is necessary to choose the appropriate curing promoter according to specific usage requirements. TTA800 has extremely low viscosity and strong dilution ability. When the amount added to the formulation exceeds 20%, a significant dilution effect can be achieved.