The hot ion curing process has the characteristics of low temperature and rapid curing, which is suitable for the adhesive formula of electronic or small components. In addition to TTA21, several other cycloaliphatic epoxy resins from Tetra have higher hot ion reaction activity, such as TTA800, TTA28, TTA22, and TTA20. To better understand their performance, the data performance will be briefly introduced below.

Since the molecular chains of TTA800, TTA28, TTA22 and TTA20 are shorter, the structure is more compact and the molecular weight is smaller, and the viscosity is extremely low (10-50cps), the molecular movement of the cationic active species and epoxy groups in the system is easier during the reaction, and it is easier to carry out hot ion polymerization reaction, so they exhibit higher hot ion reaction activity. In addition, due to the absence of ester bonds in the molecule and higher structural rigidity, the cured products of the above resins all have better water resistance and heat resistance.

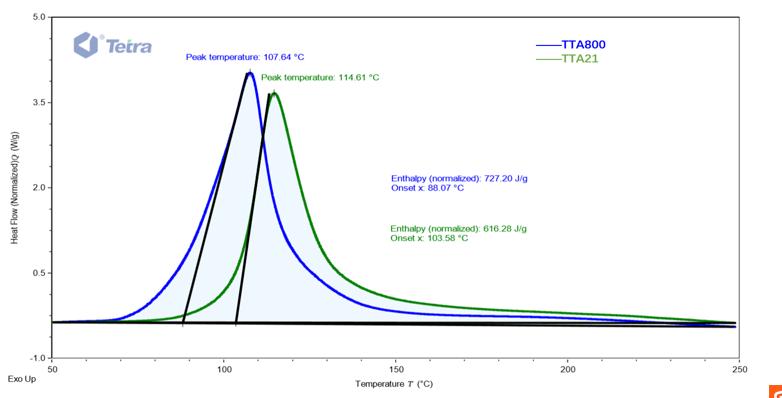

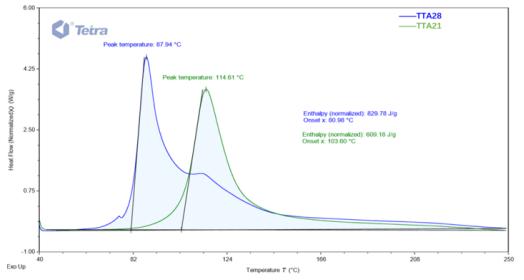

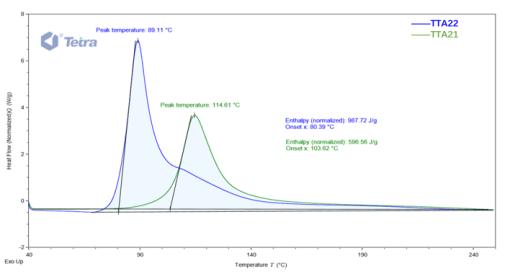

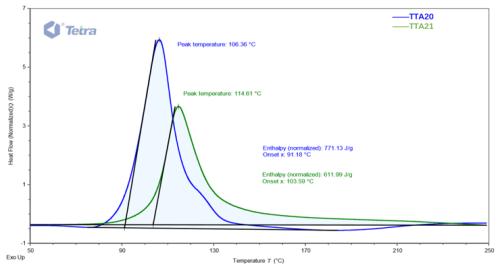

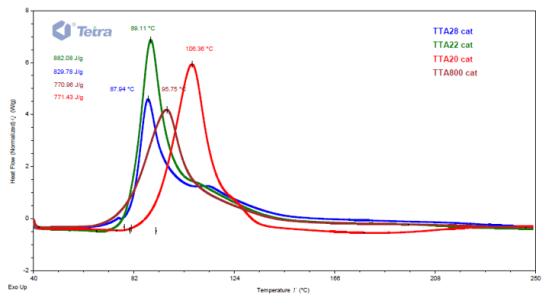

The DSC exothermic curves of the hot ion curing of the above several cycloaliphatic epoxy resins compared with TTA21 are shown in Figures 1 to 4.

Figure 1. TTA800 hot ion curing-DSC exothermic curve

Figure 2. TTA28 hot ion curing-DSC exothermic curve

Figure 3. TTA22 hot ion curing-DSC exothermic curve

Figure 4. TTA20 hot ion curing-DSC exothermic curve

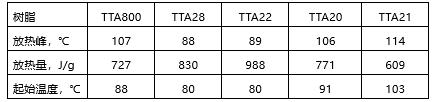

It can be summarized from the DSC exothermic curves in Figures 1 to 4 that the hot ion reaction exothermic parameters of the above several cycloaliphatic epoxy resins are shown in Table 1 below:

Table 1. Comparison of hot ion reaction DSC exothermic parameters of different resins

[Note] Resin: cationic initiator = 100:0.5 (weight ratio), where the cationic initiator is T-188 (antimony salt). In the DSC exothermic curve, the lower the reaction exothermic peak temperature and initiation temperature, and the greater the reaction exothermic quantity, the higher the reaction activity and the easier the reaction.

Figure 5. Comparison of hot ion reaction DSC exothermic curves of different resins

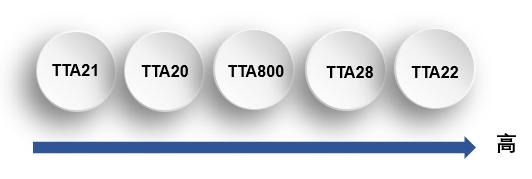

It can be concluded from the data analysis in Table 1 and Figure 5 that the hot ion reaction activity of the above several cycloaliphatic epoxy resins is compared as follows:

This indicates that TTA800, TTA20, TTA28, and TTA22 resins all have higher hot ion reaction activity. Therefore, these resins are often used in combination with TTA21 to improve the hot ion reaction activity and the performance of the cured product such as heat resistance and water resistance.

Due to the relatively high hot ion reaction activity of the above several cycloaliphatic epoxy resins, they can meet the requirements of low temperature and rapid curing, achieve low energy consumption and high efficiency with a small amount added, significantly improve the reaction rate, shorten the curing time, and improve the curing efficiency, which can also bring users more choices and convenience during use. We hope that Tetrawill's comprehensive guide on high-activity resins of cycloaliphatic epoxy resin cured by thermal cationic polymerization has provided valuable insights into this advanced system. It is crucial to highlight the significance of key compounds in these resins, such as CAS 5493 45 8, and 3 4 epoxycyclohexylmethyl methacrylate. Additionally, we must acknowledge the role of CAS 106 87 6 and CAS 5026 74 4 in enhancing the effectiveness of these high-activity resins. By understanding the unique properties and applications of these compounds, you can unlock the full potential of cycloaliphatic epoxy resins cured by thermal cationic polymerization. For further information and guidance on these resins, please reach out to our experienced team at Tetrawill.