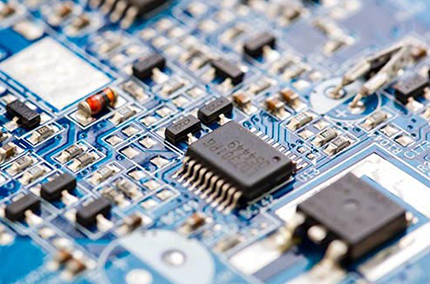

In electrical and electronic systems, resin materials not only serve structural and protective functions, but their long-term electrical insulation stability and environmental resistance often have a direct impact on equipment safety and service life.

Owing to their stable molecular structure and well-balanced performance profile, material tetra cycloaliphatic epoxy resins have attracted increasing attention in a wide range of electrical and electronic applications.

Compared with general industrial applications, the electrical and electronics industry places greater emphasis on long-term reliability. During service, materials are typically subjected to a combination of electrical stress, thermal stress, and environmental aging.

As a result, resin materials used in electrical and electronic applications are expected to provide:

Stable electrical insulation performance

Good thermal resistance and resistance to thermal shock

Resistance to humidity, moisture, and chemical exposure

Minimal performance degradation over long-term operation

Cycloaliphatic epoxy resins have been introduced into this field largely in response to these core requirements.

Cycloaliphatic epoxy resins are based on saturated alicyclic structures and do not contain aromatic rings. This structural feature is particularly important in electrical and electronic applications.

On one hand, the saturated molecular structure is more stable under electric fields, contributing to lower dielectric loss. On the other hand, the highly crosslinked network formed after curing effectively restricts molecular chain mobility, thereby enhancing the stability of electrical insulation performance under varying environmental conditions.

In electronic encapsulation and protection systems, resin materials must provide not only mechanical support but also reliable environmental isolation for sensitive components.

In such applications, cycloaliphatic epoxy resins demonstrate:

Dense and stable encapsulation structures

Effective barriers against moisture and contaminants

Consistent electrical performance during long-term use

Their inherently low yellowing behavior makes them particularly suitable for LEDs, optical devices, and other applications where appearance and light transmission stability are critical.

During actual operation, electrical and electronic equipment is often exposed to temperature fluctuations and humid environments. The ability of materials to maintain performance under such conditions is a key indicator of reliability.

Cycloaliphatic epoxy resins exhibit good dimensional stability under thermal cycling and relatively low moisture absorption, helping to reduce the impact of environmental factors on electrical insulation performance and structural integrity.

In electronic manufacturing processes, resin materials must also offer adequate processing flexibility. Cycloaliphatic epoxy resins are suitable for both conventional thermal curing systems and UV cationic curing systems.

While enabling rapid curing and low shrinkage, their ability to continue curing in complex or shadowed areas provides greater process flexibility for the design of electronic encapsulation and insulation materials.

As electrical and electronic products increasingly demand higher safety levels and longer service life, material selection is shifting from simply meeting initial performance targets toward ensuring long-term reliability.

With their combined advantages in electrical performance stability, environmental resistance, and process adaptability, cycloaliphatic epoxy resins are becoming an increasingly important class of high-performance materials for electrical and electronic applications.

This is the first one.